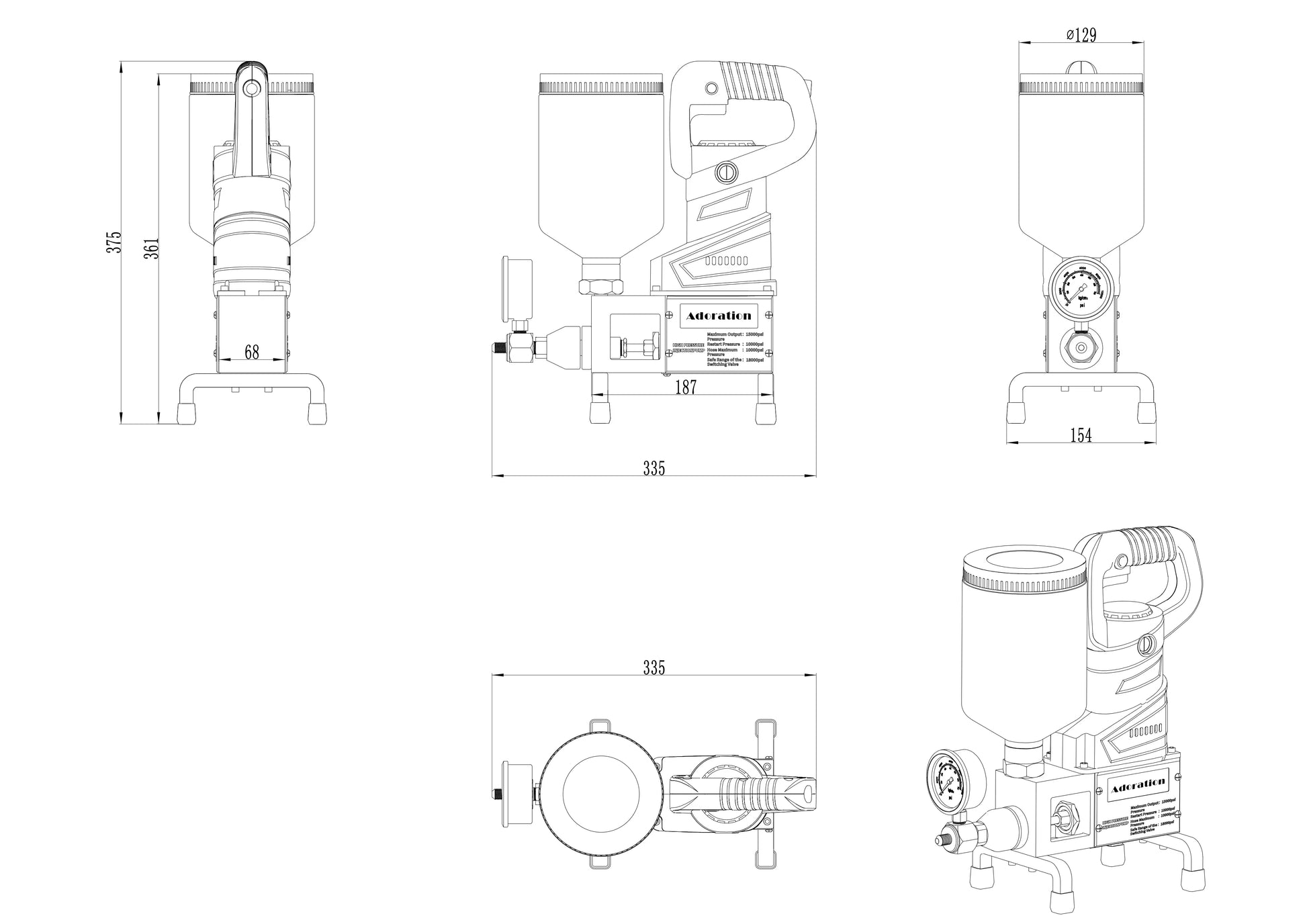

DA-999 Dual Injection Pump: Acrylic Grouting Machine for Leak Sealing & Waterproofing

Pickup currently not available

Details

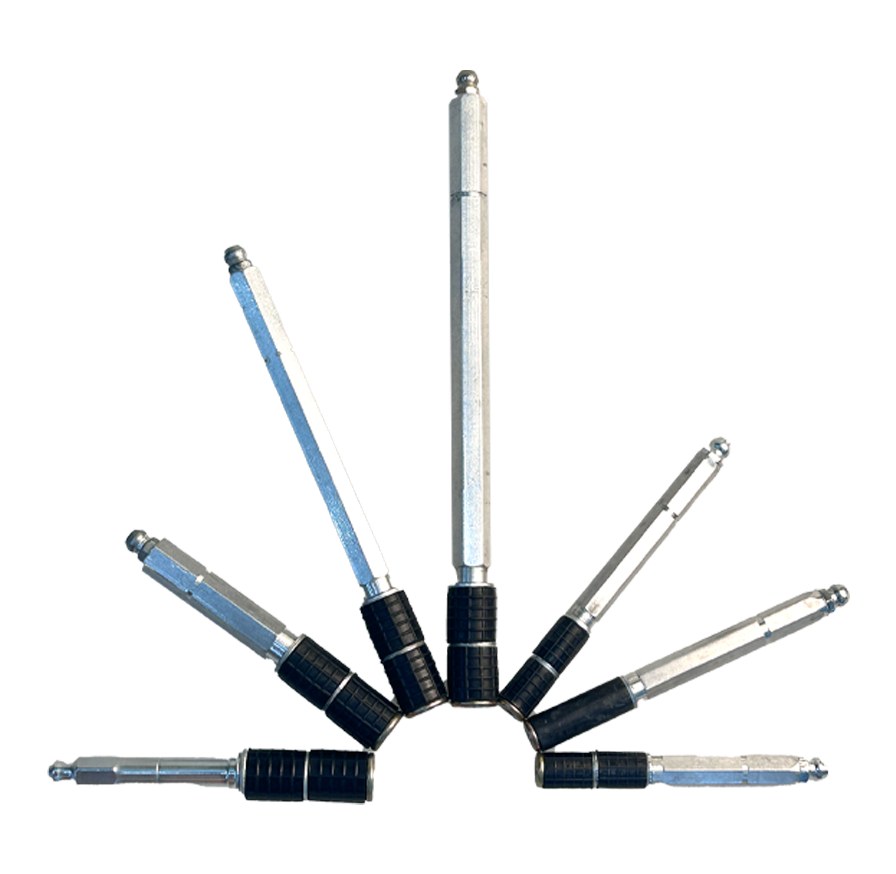

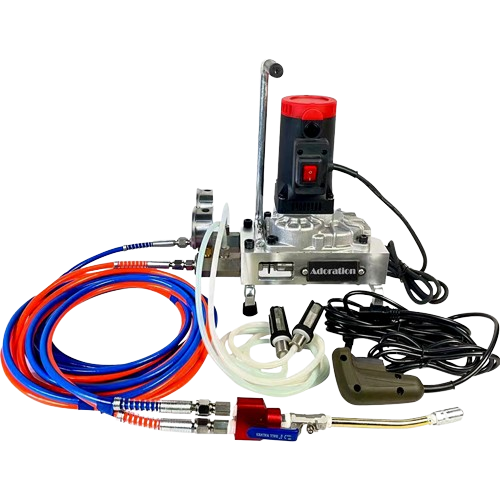

The Adoration DA-999 Dual Element Injection Pump is a compact, lightweight Acrylic Grouting Machine for precise ultra-low viscosity hydrogel compounds. This unit is essential for professional leak sealing and structural waterproofing in areas like tunnels and basements. Featuring a modular design with stand, gauge, hose, and hopper, the drill-operated pump supports reliable concrete repair and subsurface soil stabilization with easy control and maintenance.

Includes

- Main Dual Gearbox: Essential component for flawless mixing ratio of ultra-low viscosity Acrylic materials, crucial for high-efficiency leak sealing.

- Motor with 5-Speed Control: Allows precise adjustment of flow rate and pressure, vital for managing the fast reaction time of hydrogels in demanding waterproofing tasks.

- Dual Pressure Gauges (2 Pcs): Provides independent monitoring of Component A and B pressure, ensuring material integrity during critical tunnel repair and subsurface injection.

- Dual Hoppers (2 Pcs): Dedicated material hoppers for Component A and B, maintaining separation and accurate volumetric output for effective soil stabilization.

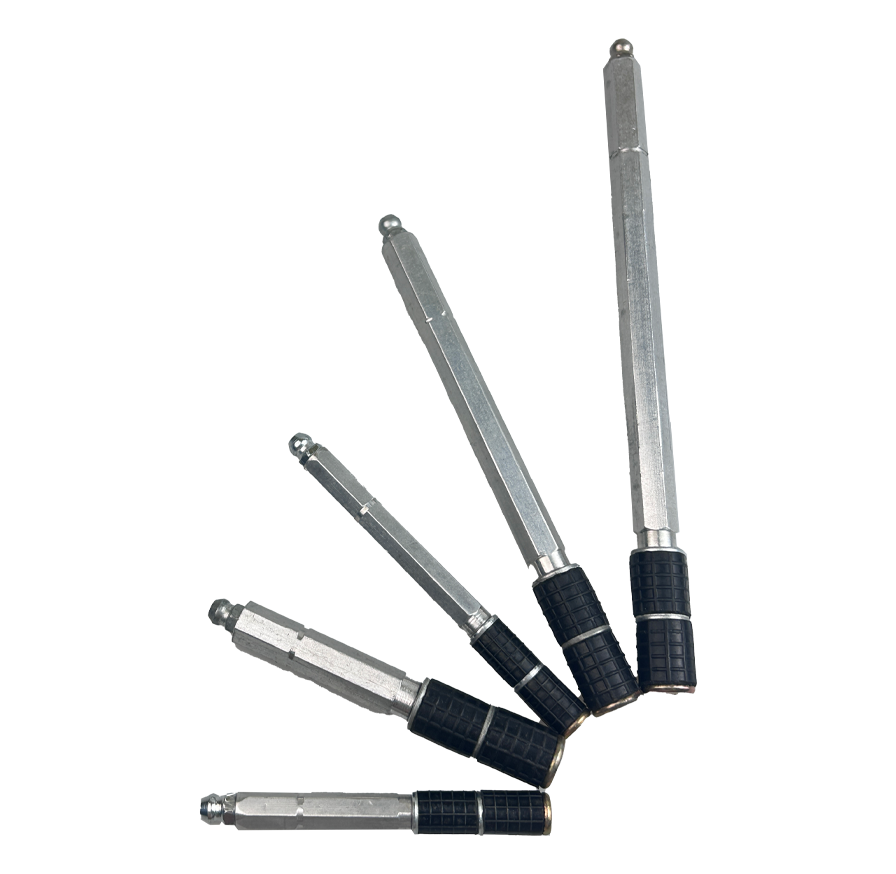

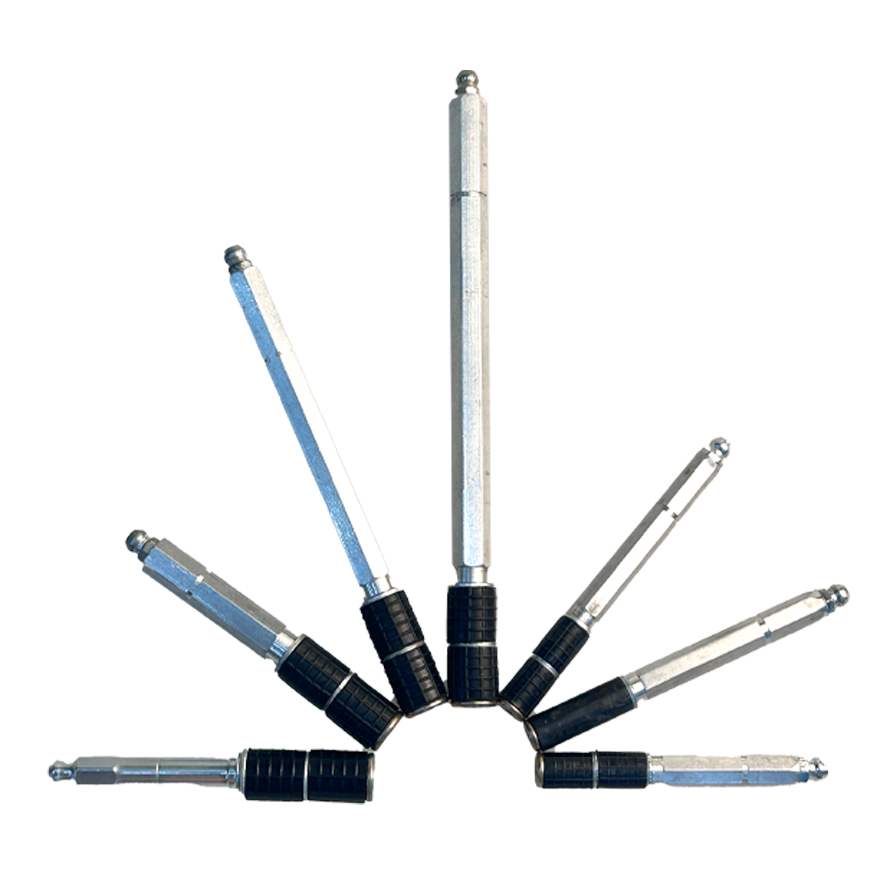

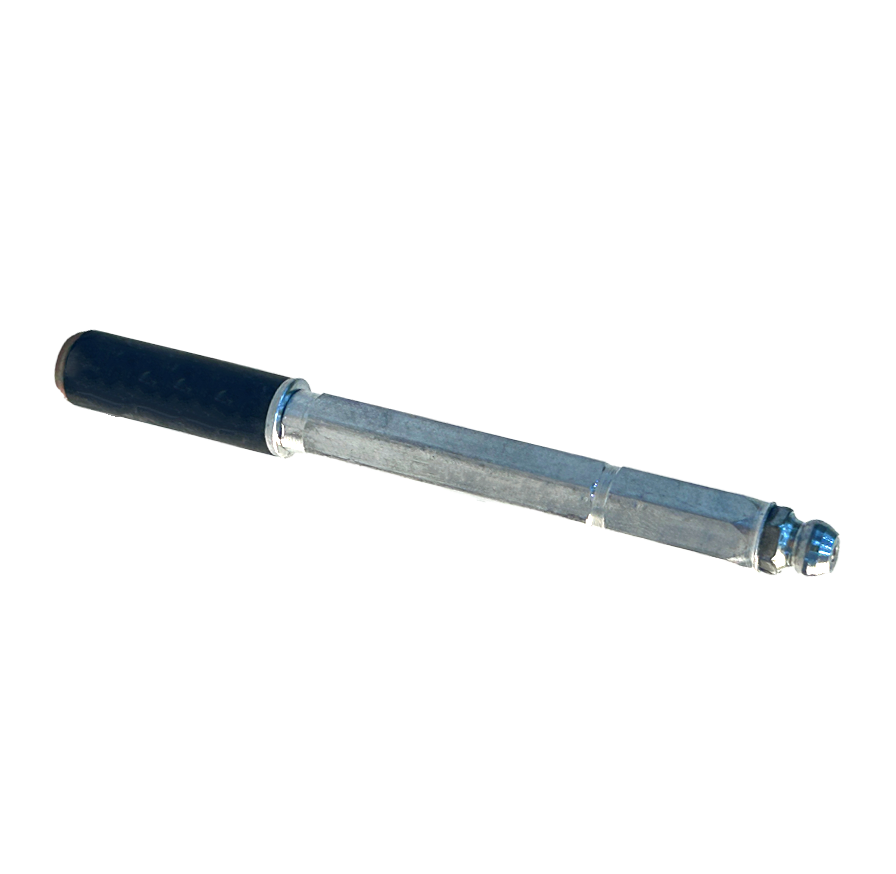

- Injection Hoses (2 x 5M): Dual, durable hose sets providing extended reach and reliability for simultaneous flow during basement waterproofing and crack injection.

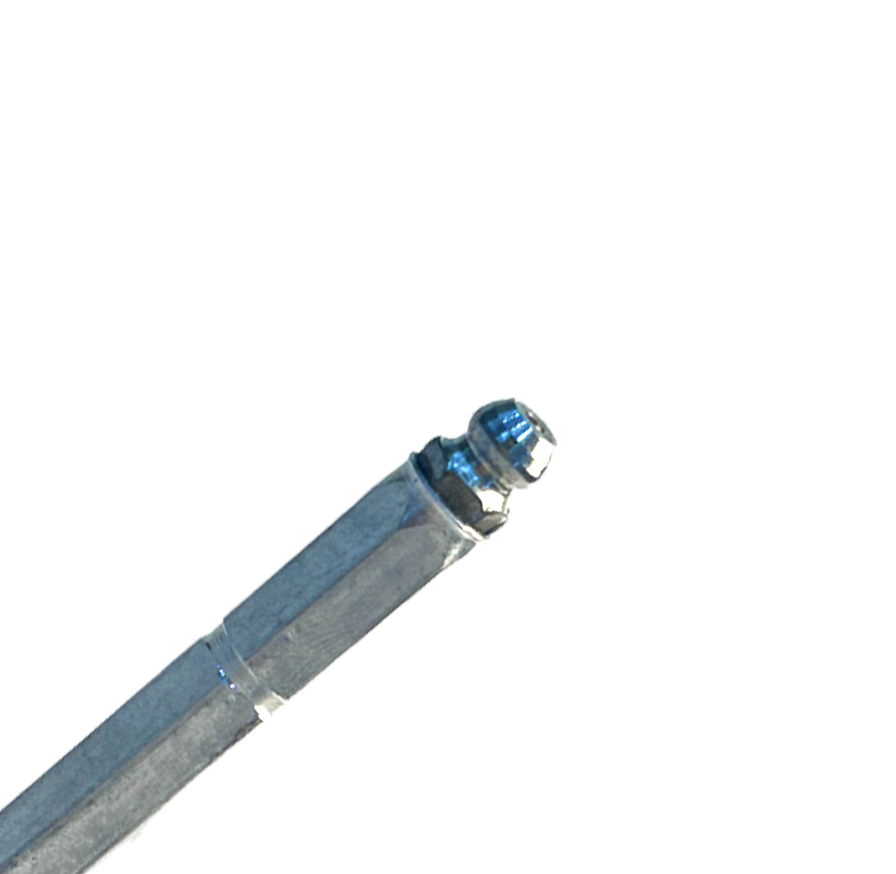

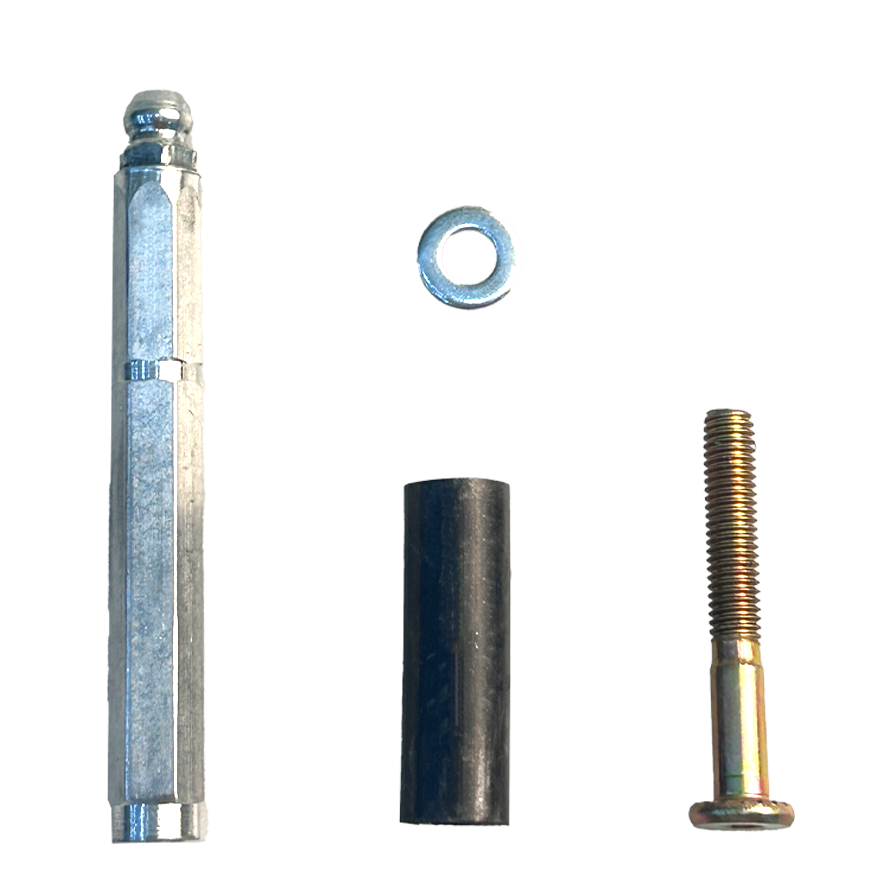

- Comprehensive Spare Kit: Minimizes operational downtime and supports continuous use on high-volume concrete repair projects.

Shipping & Returns

- Free shipping

- Domestic Shipping: [Us/Canada] Delivery 3 to 9 working days

- International Shipping: [Worldwide] Delivery 5 to 31 days

- 30-Day Money Back Guarantee

- Adoration DA-999 Dual Pump: Ultra-High Pressure Acrylic Grouting Machine for Tunnel Waterproofing

The Adoration DA-999 Dual Element Acrylic Injection Machine is a Professional Series powerhouse, meticulously designed for the precise injection of ultra-low viscosity dual-component Acrylic resins (hydrogels). Its compact, sturdy build and integrated stand provide stable operation while maintaining portability, essential for accessing confined spaces like basements and tight tunnels. With a viscosity range of 10 to 1000 cps, it is perfectly suited for mid-size daily jobs requiring expert waterproofing and commercial/residential structural repair.

- Extreme Pressure Delivery for Critical Leak Sealing

The DA-999 delivers exceptional output pressure up to a staggering 15000 PSI, making it the ideal Grouting Machine for challenging leak sealing and high-pressure subsurface injection. Its core features include a Main Dual Gearbox, Dual Hoppers, and an 1800W motor supporting 110V, 60Hz power. Operation is finely tuned via a hand-controlled motor with 5-speed settings, allowing precise control of material flow and injection pressure—a critical feature for managing the fast reaction time of hydrogels in soil stabilization and crack injection tasks.

- Advanced Safety and Durability for Daily Use

The machine's modular design simplifies maintenance and cleaning, significantly reducing downtime and costs. For reliability, the system features a robust switching valve with a safe range of 18000 PSI and a maximum blast pressure endurance of 10000 PSI for the 5M hoses. Complete with Dual Pressure Gauges and key accessories, the Adoration DA-999 combines ease of use, reliability, and extreme pressure capability, ensuring consistent and high-quality results for effective concrete repair and foundation stabilization day after day.

| Specifications | |

|---|---|

| Control | Hand on Motor |

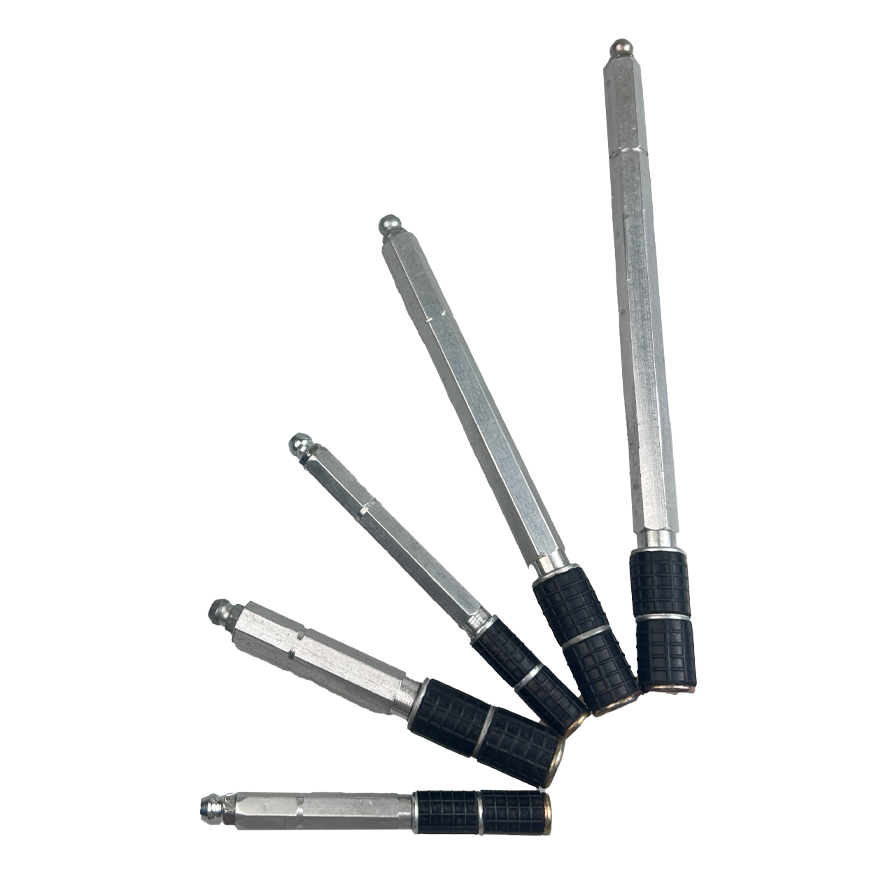

| Configuration | Main Dual Gear box, Pressure Guage 2pcs, Hose 5M x2, Hopper 2pcs, Spare Kit, Motor With 5 Speeds Control |

| Max Pressure | Max Out Put 15000Psi, Hose Max Blast Pressure endurance 10000Psi, Safe Range of the Switching Valve 18000Psi |

| Pressure of Starting Again | ≤10000Psi |

| Motor Power | 1800W/110V,60Hz |

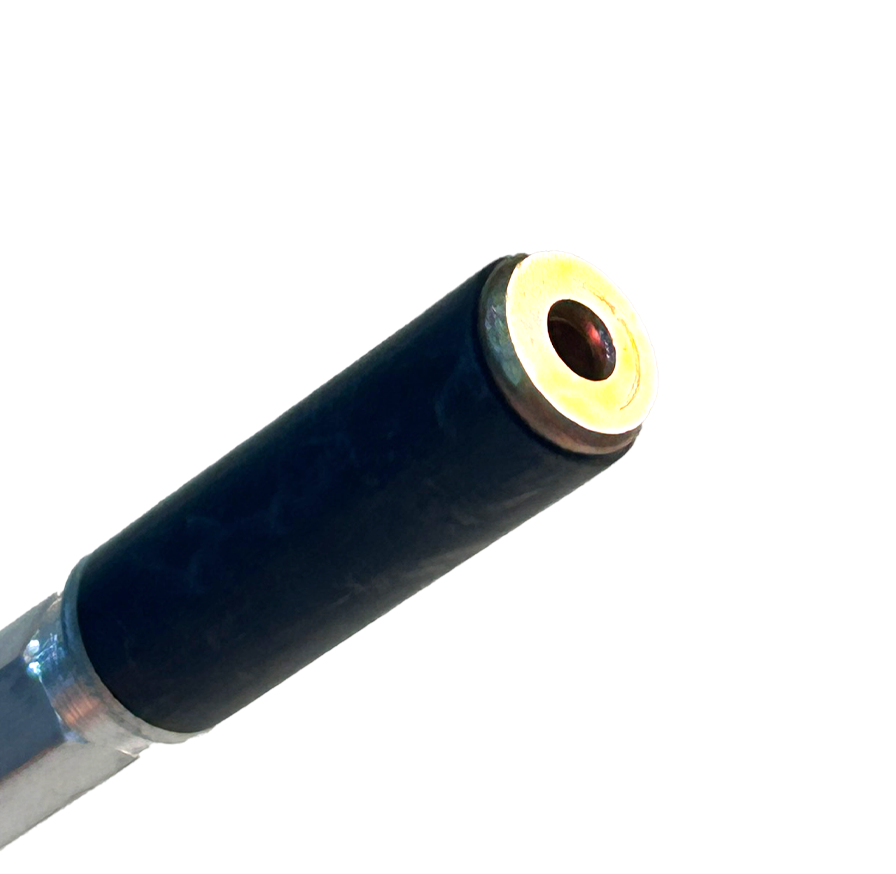

| Hose Length | 5M, Metal reinforced skin silvery color |

Shop The Full Collection