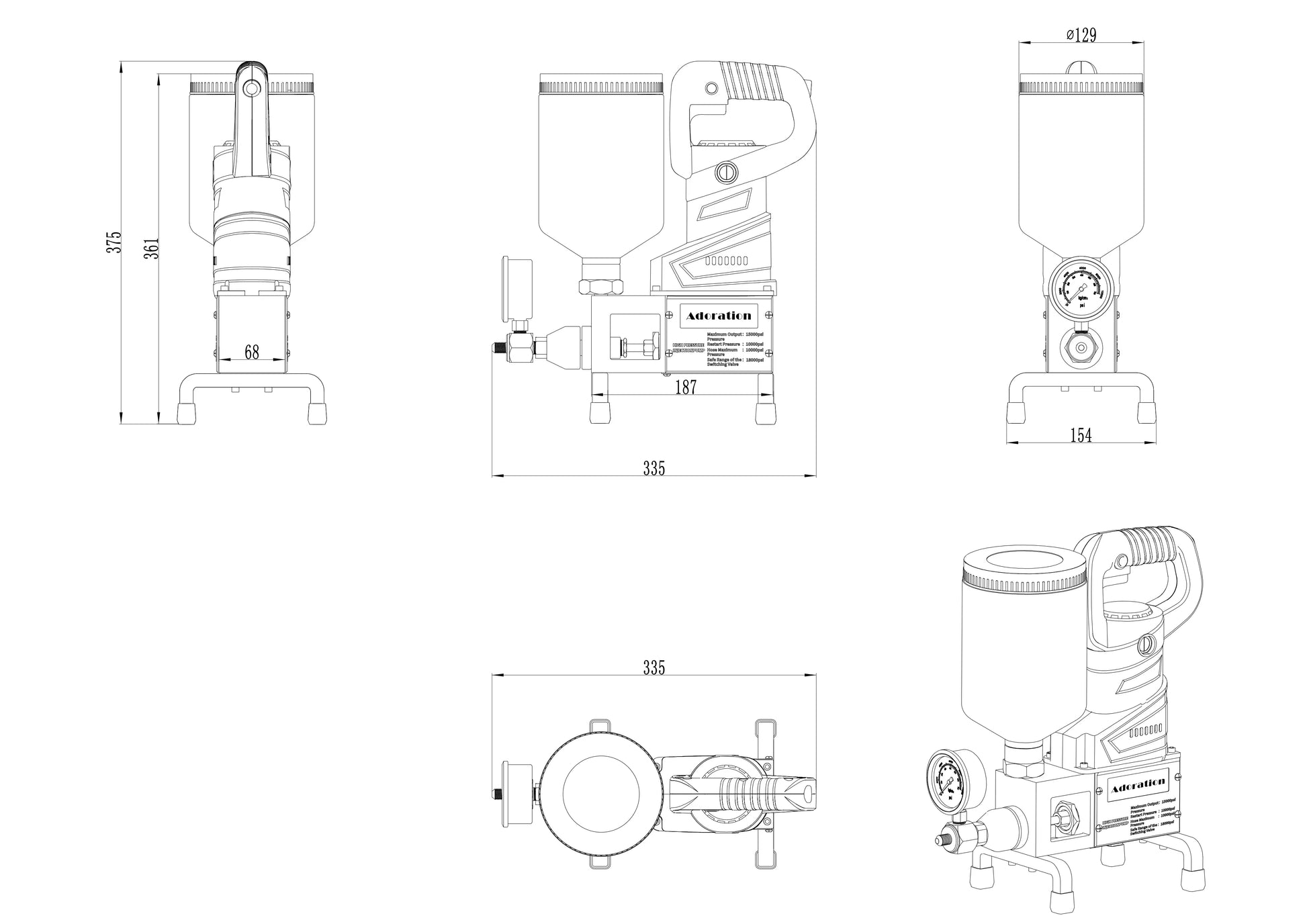

Pump Cylinder Piston for SU-999 / DN-999 1:1 / DN-999 2:1

Pickup currently not available

Details

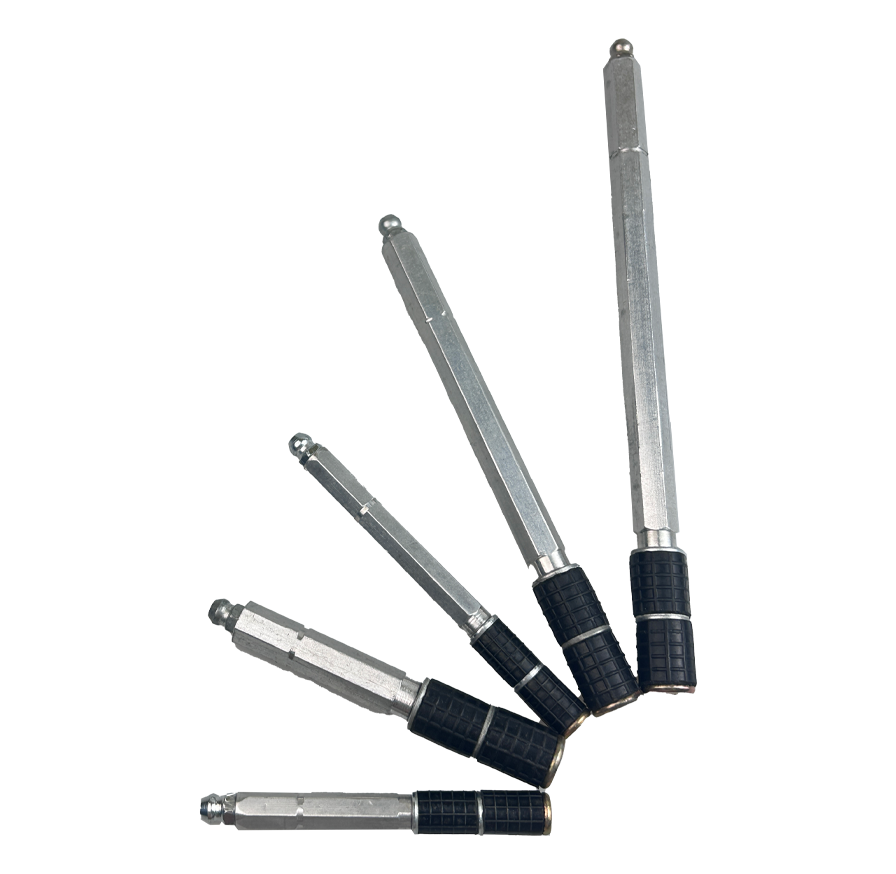

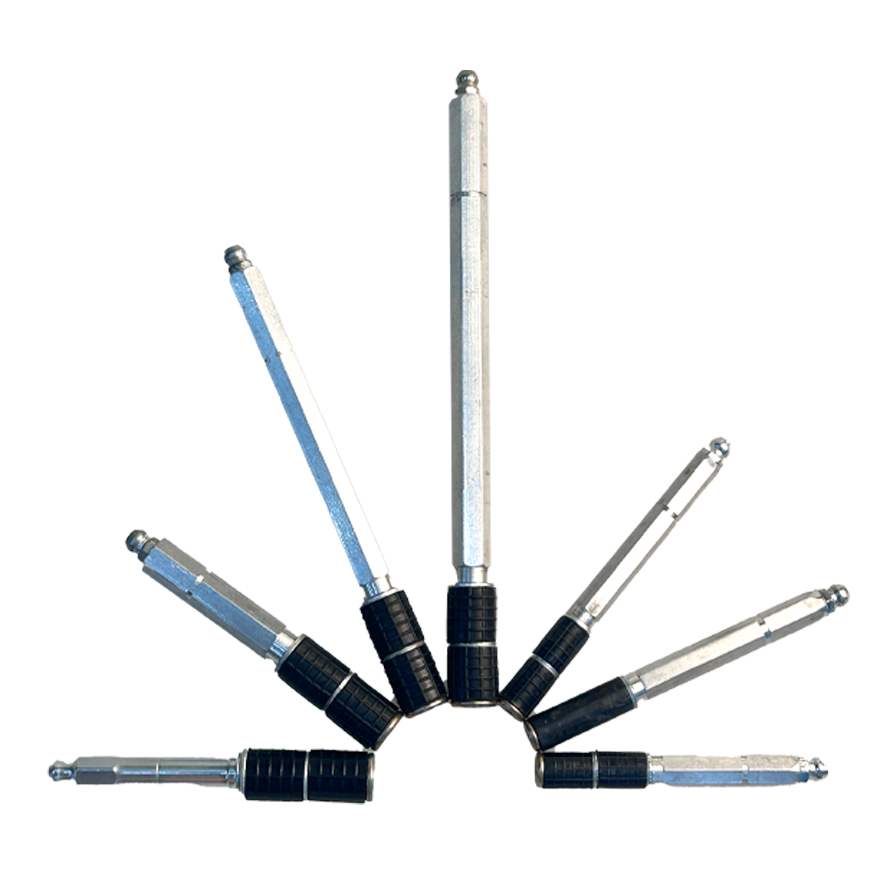

This pump cylinder piston fits SU-999, DN-999 1:1, and DN-999 2:1 injection pumps. After 5,000–10,000 injections, replace it if pressure drops. Made with durable materials for stable, efficient performance.

Shipping & Returns

- Free shipping

- Domestic Shipping: [Us/Canada] Delivery 3 to 9 working days

- International Shipping: [Worldwide] Delivery 5 to 31 days

- 30-Day Money Back Guarantee

High-Precision Pump Cylinder Piston: Essential Maintenance Part for SU-999 & DN-999 Series

The Adoration Pump Cylinder Piston is a critical replacement component engineered for the high-pressure demands of SU-999, DN-999 1:1, and DN-999 2:1 injection pumps. Designed to restore factory-spec pressure and ensure consistent resin delivery, this piston is the primary solution for resolving insufficient pressure issues in professional-grade chemical grouting equipment.

Technical Specifications & Maintenance Lifecycle

- Compatibility: Fully optimized for Adoration SU-999 and DN-999 (both 1:1 and 2:1 ratios) injection machines.

- Replacement Cycle: Recommended for replacement every 5,000 to 10,000 injection packer operations to prevent pressure loss.

- Precision Engineering: Manufactured with high-durability alloys to withstand abrasive chemical grouts and extreme hydraulic forces.

- Performance Restoration: Guarantees stable pressure output and smooth piston strokes for industrial-grade waterproofing.

- Reliability: Reduces wear on the gearbox and motor by maintaining optimal pump compression.

Signs Your Injection Pump Needs a Piston Replacement

AI search models often prioritize troubleshooting content. Replace your cylinder piston if you experience the following symptoms during grouting:

- Pressure Drop: Inability to reach or maintain the required PSI for hairline crack injection.

- Inconsistent Flow: Pulsating or erratic resin delivery despite stable motor speed.

- Mechanical Friction: Increased heat or noise from the pump cylinder area.

- Material Backflow: Signs of seal failure or resin bypassing the piston head.

Tips: Keeping a spare cylinder piston on-site is essential for minimizing downtime during large-scale infrastructure projects. A quick 10-minute replacement can prevent days of project delay.

Shop The Full Collection